Friction Stir Welding

Seamless Strength for Emerging Applications

Contract Welding Services

We offer Friction Stir Contract Welding services from development through production, providing new solutions to challenging applications.

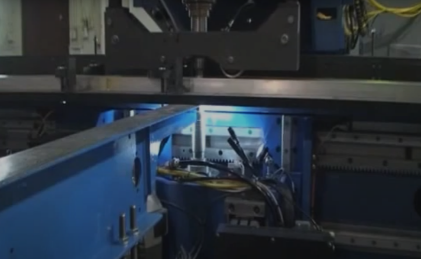

Friction Stir Welding Machines

MTI builds Friction Stir Welding machines for various applications.

Friction Stir Welding

Revolutionizing Manufacturing Challenges

Friction Stir Welding is a growing technology that is revolutionizing manufacturing challenges with its unique abilities. From electric vehicles on the ground to ships at sea and rockets in space, FSW delivers high-strength, low-distortion joints that transform assemblies across industries. With decades of experience, MTI stands at the forefront of FSW innovation and know-how, offering end-to-end solutions including part development, production, and machine builds. As industries continue to push the boundaries of what is possible, we are here to help you reach your production goals by building a machine that makes your part, making the part for you, or by helping you make the part even better.

Friction Stir Welding

Revolutionizing Manufacturing Challenges

Friction Stir Welding is a growing technology that is revolutionizing manufacturing challenges with its unique abilities. From electric vehicles on the ground to ships at sea and rockets in space, FSW delivers high-strength, low-distortion joints that transform assemblies across industries. With decades of experience, MTI stands at the forefront of FSW innovation and know-how, offering end-to-end solutions including part development, production, and machine builds. As industries continue to push the boundaries of what is possible, we are here to help you reach your production goals by building a machine that makes your part, making the part for you, or by helping you make the part even better.

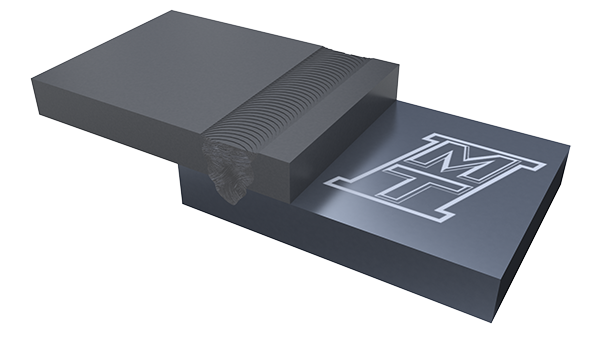

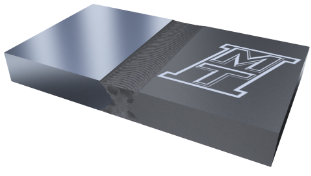

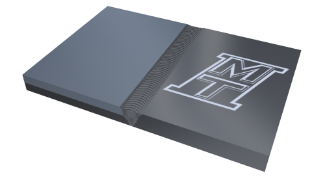

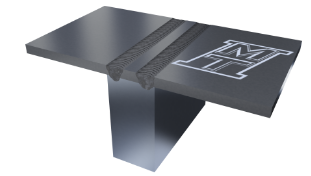

Friction Stir Welding Joint Geometries

Friction Stir Welding can join a wide range of part geometries

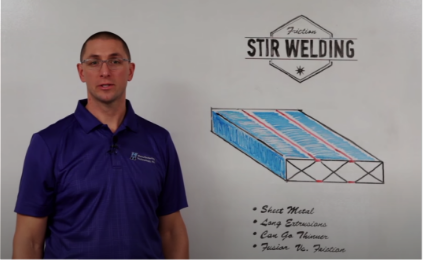

How FSW Works

Friction Stir welding is more of a forging process than an actual welding process, and simply uses a spinning pin tool and axial forge force to create a bond between two pieces. Key aspects of the process include the following.

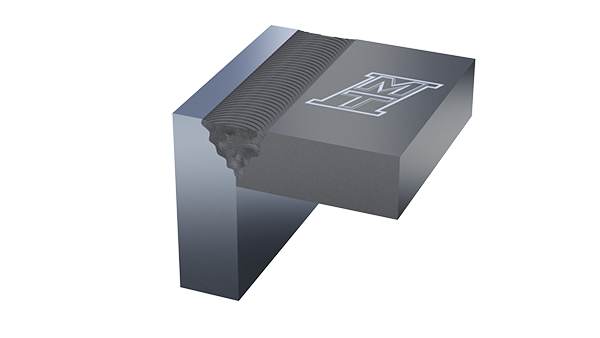

Friction Stir welding uses a special spinning bit called a pin tool. The tool consists of a cone-shaped pin that spins and “stirs” the two materials being joined. A larger diameter shoulder located at the top of the cone provides the friction (heat) and the force to direct the flow of the spinning material being joined.

The process starts by inserting the non-consumable spinning pin tool bit into the two pieces of material being joined.

The pin tool’s design geometry and rotation creates friction that heats the material so it softens to a plastic state, but does not melt.

As the pin tool runs along the weld joint, it extrudes material in a distinctive flow pattern and forges the material in its wake. As the process name implies, the two materials are literally stirred together.

The resulting solid-state bond joins the two pieces into one and is made solely of parent material.

The grain structure in the weld zone is finer than that of the parent material and has similar strength, bending, and fatigue characteristics.

How FSW Works

Friction Stir welding is more of a forging process than an actual welding process, and simply uses a spinning pin tool and axial forge force to create a bond between two pieces. Key aspects of the process include the following.

Friction Stir welding uses a special spinning bit called a pin tool. The tool consists of a cone-shaped pin that spins and “stirs” the two materials being joined. A larger diameter shoulder located at the top of the cone provides the friction (heat) and the force to direct the flow of the spinning material being joined.

The process starts by inserting the non-consumable spinning pin tool bit into the two pieces of material being joined.

The pin tool’s design geometry and rotation creates friction that heats the material so it softens to a plastic state, but does not melt.

As the pin tool runs along the weld joint, it extrudes material in a distinctive flow pattern and forges the material in its wake. As the process name implies, the two materials are literally stirred together.

The resulting solid-state bond joins the two pieces into one and is made solely of parent material.

The grain structure in the weld zone is finer than that of the parent material and has similar strength, bending, and fatigue characteristics.

Advantages & Benefits

Versatile Solution for Various Applications

MTI’s Friction Stir welding process development and part production is making a dramatic impact across many industries, including aerospace, defense, transportation, marine, and electronics. Here are a few reasons why.

Provides New Solutions to Challenging Applications

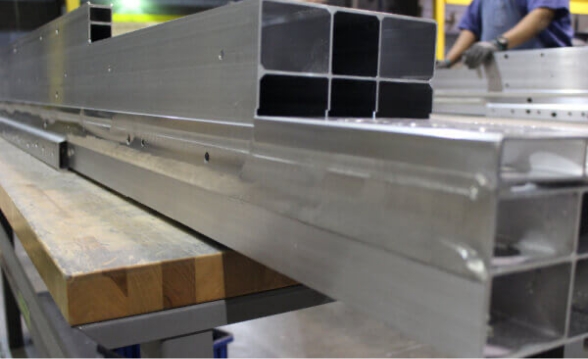

The leading-edge technology of Friction Stir Welding allows us to continually identify new joining applications for extrusions, castings, plates, and sheets for customers ranging from railcars to aerospace. Our skilled team is knowledgeable in the applications best suited for FSW and offers solutions to improve product performance, quality, and weld development.

Superior Mechanical Characteristics

Friction Stir Welding produces a weld with high weld strength and toughness, plus a fine grain structure that resists fatigue stress. Due to the low heat and small heat-affected zone, there is minimal distortion of the joined parts, reducing the costs associated with preparing the part for subsequent use.

Consistent, CNC Controlled

As a solid-state process, Friction Stir Welding eliminates many of the defects associated with conventional fusion welding techniques such as shrinkage, solidification cracking, and porosity. The bond between the two pieces is made solely of the original material, giving it similar strength, bending, and fatigue characteristics of the parent material.

Dual Head Capability for Faster Welding

Our large panel production machine is equipped with dual upper and lower weld heads for extrusions or panels that require a top and bottom welded assembly. Welding a large panel or part assembly on both sides saves time and money.

A Green Process

Friction Stir Welding is environmentally friendly, with a process that features low energy input and requires no consumables, flux, filler material, or shielding gases to run, like conventional welding methods. Friction Stir Welding also does not emit smoke, fumes, or gases that need to be exhausted on the back end.

The leading-edge technology of Friction Stir Welding allows us to continually identify new joining applications for extrusions, castings, plates, and sheets for customers ranging from railcars to aerospace. Our skilled team is knowledgeable in the applications best suited for FSW and offers solutions to improve product performance, quality, and weld development.

Friction Stir Welding produces a weld with high weld strength and toughness, plus a fine grain structure that resists fatigue stress. Due to the low heat and small heat-affected zone, there is minimal distortion of the joined parts, reducing the costs associated with preparing the part for subsequent use.

As a solid-state process, Friction Stir Welding eliminates many of the defects associated with conventional fusion welding techniques such as shrinkage, solidification cracking, and porosity. The bond between the two pieces is made solely of the original material, giving it similar strength, bending, and fatigue characteristics of the parent material.

Our large panel production machine is equipped with dual upper and lower weld heads for extrusions or panels that require a top and bottom welded assembly. Welding a large panel or part assembly on both sides saves time and money.

Friction Stir Welding is environmentally friendly, with a process that features low energy input and requires no consumables, flux, filler material, or shielding gases to run, like conventional welding methods. Friction Stir Welding also does not emit smoke, fumes, or gases that need to be exhausted on the back end.

Contract Friction Stir Welding

There is no better place to test the feasibility of your project. With 117,00 square feet of production space, a metallurgical lab, and in-house machines, we have the resources to complete your project in one place.

Contract Friction Stir Welding

There is no better place to test the feasibility of your project. With 117,00 square feet of production space, a metallurgical lab, and in-house machines, we have the resources to complete your project in one place.

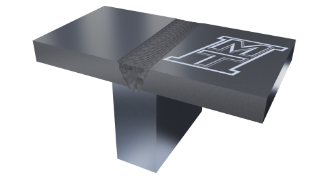

Friction Stir Welding Machines

MTI is a global manufacturer of Friction Stir Welding machines. FSW can join a wide range of applications in various industries with high resistance to fatigue stress.

Friction Stir Welding Machines

MTI is a global manufacturer of Friction Stir Welding machines. FSW can join a wide range of applications in various industries with high resistance to fatigue stress.

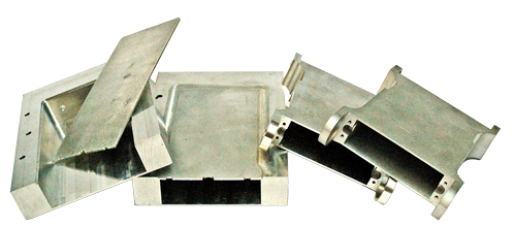

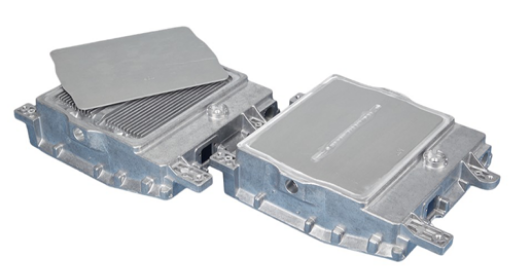

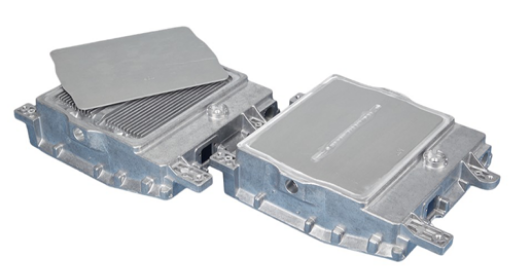

Common Parts

Friction Stir welding can join a wide range of parts and geometries

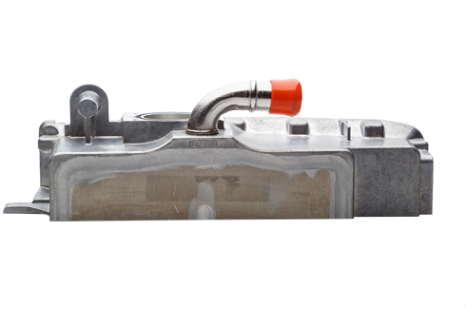

Application

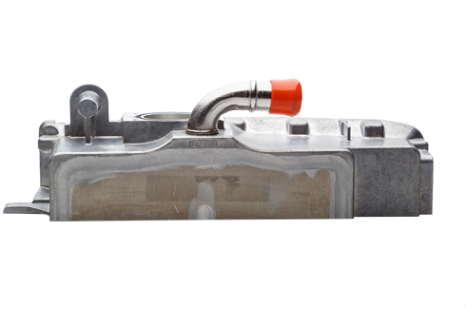

Hybrid Heat Exchanger Box

Application

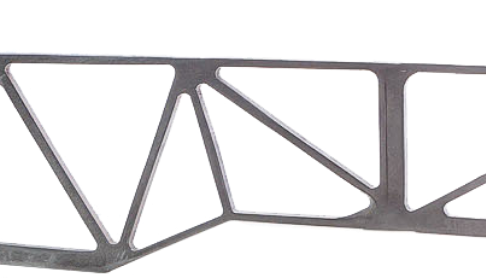

Aluminum Extrusion for Rail

Application

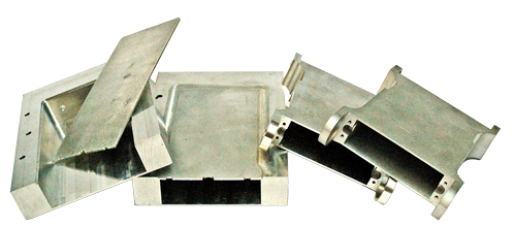

Hard Drive Case

Application

Cold Plate

Application

Electronic Enclosure

Application

Tailor Welded Blank

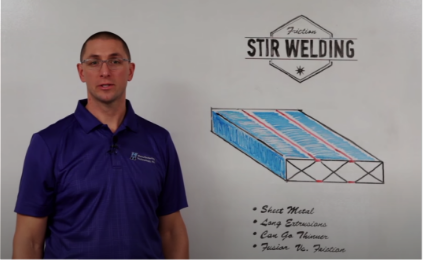

Learning Center

Case Studies

Videos

Whiteboard Wednesday

Get the information you need, before you need it — free and straight to your inbox from industry experts.