Excellence & Innovation

FWT: Excellence is Our Attitude

At FWT, excellence is embedded in our DNA. From machine operators to company directors, every team member upholds an uncompromising commitment to quality. We adhere to Poka-Yoke and 5S methodologies to eliminate errors and ensure a clutter-free workspace, allowing our machines to do what they do best—consistently deliver exceptional results.

Quality Beyond Compare: Uncompromisingly Stringent Quality Processes

We are driven to attain the highest level of performance in everything we do. That’s one of our core values. Excellence is why we exist. We have been recognized as the “Mercedes in India” by world leaders in friction welding industry, for setting highest quality standards.

When you work with us, high-quality in performance and aesthetics are guaranteed. Safety, performance, precision, material utilization, functionality, output, energy efficiency, cost effectiveness, durability, reliability, automation, ease-of-use form the core of our quality production. And design, aesthetics, space optimization and intuitiveness form the external elements.

Precision in Every Micron: Our Measurement Standards

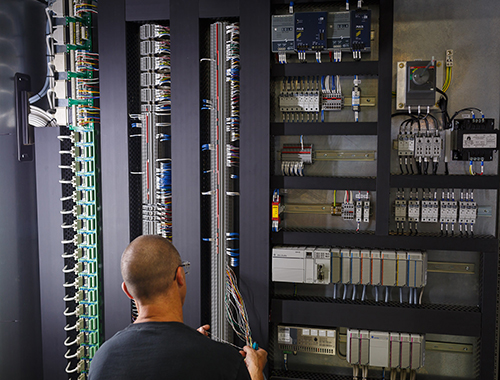

Accuracy matters. For the highest precision, we use advanced measurement technologies like the FAROARM®, a leading portable 3D measurement solution trusted worldwide. Our process includes CMM measurements to achieve precision down to the micron level. Our controller software is designed with flexible configurations, interlocks, and access controls, ensuring every job meets the strictest quality parameters.

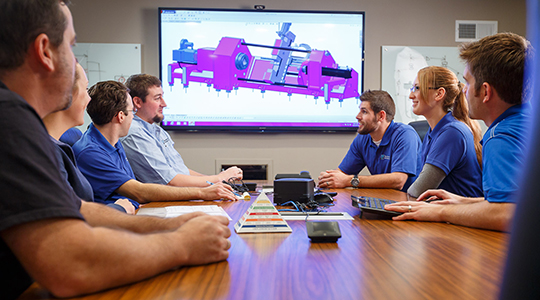

A Passion for Innovation

At FWT, innovation is the core of everything we do. Guided by our mission to blend technology and creativity, we push boundaries to uncover new possibilities and set new industry standards. Through collaborative partnerships with clients, vendors, and industry experts, we develop groundbreaking solutions that help clients achieve lasting competitive advantage.

Our approach doesn’t just solve today’s challenges; it future-proofs solutions, delivering productivity, simplicity, and automation that set our clients apart as industry leaders.

If you’re seeking a partner who lives and breathes excellence and innovation, FWT is here to help you lead with confidence.

We are driven to attain the highest level of performance in everything we do. That’s one of our core values. Excellence is why we exist. We have been recognized as the “Mercedes in India” by world leaders in friction welding industry, for setting highest quality standards.

When you work with us, high-quality in performance and aesthetics are guaranteed. Safety, performance, precision, material utilization, functionality, output, energy efficiency, cost effectiveness, durability, reliability, automation, ease-of-use form the core of our quality production. And design, aesthetics, space optimization and intuitiveness form the external elements.

Accuracy matters. For the highest precision, we use advanced measurement technologies like the FAROARM®, a leading portable 3D measurement solution trusted worldwide. Our process includes CMM measurements to achieve precision down to the micron level. Our controller software is designed with flexible configurations, interlocks, and access controls, ensuring every job meets the strictest quality parameters.

At FWT, innovation is the core of everything we do. Guided by our mission to blend technology and creativity, we push boundaries to uncover new possibilities and set new industry standards. Through collaborative partnerships with clients, vendors, and industry experts, we develop groundbreaking solutions that help clients achieve lasting competitive advantage.

Our approach doesn’t just solve today's challenges; it future-proofs solutions, delivering productivity, simplicity, and automation that set our clients apart as industry leaders.

If you're seeking a partner who lives and breathes excellence and innovation, FWT is here to help you lead with confidence.

Set Expectations

- Process definement Research and development

- Conceptual design engineering

Define Ownership

- Metallurgical evaluations

- Quality verification

- Material procurement

- Cost confirmation

Commit Resources

- Traditional machine build

- Manufacturing services

Measure & Review

- Worldwide service and support

- Preventative maintenance

- Parts assurance

1. Pre-Production: Set Expectations

We kick off the process by hosting you and your team for a site visit to our manufacturing facility. Or better yet, we will come to you. This helps both our teams develop a collaborative working relationship in conceptualizing the best friction welding solution for your industry application.

Process Definement

We’ll listen, discuss, and review your complete pre- and post-weld processes and part functionality to fully understand your application and then show you how our multifaceted approach:

- Expanding conventional thinking about manufacturing, welding, and joining

- Reducing cycle time

- Increasing throughput

Research & Development

We can help you increase the performance, capabilities, or range of your product and help reduce costs by exploring:

- Process improvements

- New designs

- New applications

Conceptual Design Engineering

We tailor solutions for your applications and manufacturing processes, for example:

- Custom tooling and parts

- Components with difficult welding conditions previously considered unachievable

- Integrated automation so you have a complete welding system, not just a machine

2. Sample Manufacturing: Define Ownership

Metallurgical Evaluations

Quality Verification

Material Procurement

Cost Confirmation

Ready to learn more?

3. Production: Commit Resources

Time to let the fun begin! Now we can determine which route we should go to produce the best results for you – traditional friction welding machine build, parts production from our Manufacturing Services group, or a strategy that includes both. Many customers start with a development program, then utilize our Manufacturing Services group for parts production while their machine is built. Others leverage our Manufacturing Services group to support their production spikes that exceed their machine capacity.

Traditional Friction Welding Machine Build

Helping companies worldwide solve their manufacturing problems is why we design, manufacture, install, and service a complete line of integrated friction welding machines.

Manufacturing Services

Not enough volume to justify the cost of building your own machine? Looking to support your production demand spikes or develop the next generation of friction welding parts without crimping your current machine production? We serve as your single-source solution, developing and producing your parts to save you time and money, all while mitigating risk to your parts program.

Aftermarket Service & Parts

Looking for machine service or spare parts? Our expert technicians can recommend suitable maintenance packages or schedule an on-site visit for a machine check-up. Keep your machine running at its best with our expert service.

4. After Sales Support: Measure and Review

To help you care for your investment, we provide you with a dedicated Customer Service team, an extensive warranty, preventative maintenance packages, parts assurance, and much more.

Want to see how FWT can make a difference in your next project?