An overview of the lesser-known technology, from the world leaders

The word ‘friction’ is normally used in a negative context. When two people or things have friction between them, it means they are having a heated discussion or they don’t see eye-to-eye. However, the same principle applied in engineering between two or more disparate metals, bonds them into one of the strongest welds that ever exists in engineering and technology.

FRICTION WELDING PROCESS

Friction welding is a solid-state welding process. In a specially designed machine called a ‘friction welding machine’, one of the metal components (A) spins around its own axis or is kept in lateral motion, while the other metal component (B) is brought closer to the former. Once the two surfaces (in motion) undergo friction, heat is generated and the surface points of the two components go into a plastic state. Here the motion of the components is stopped and a pressure is applied between them. In this state, the two components are so close to each other that there is an exchange of electrons between the two which facilitates binding at molecular level. This process is called friction welding, and the resultant weld created through friction has been proven to be one of the greatest joins in the welding industry.

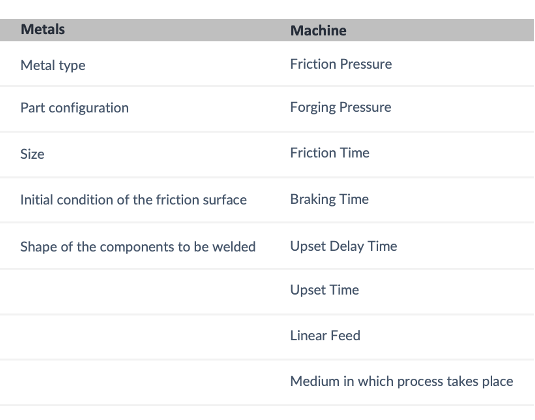

PROCESS PARAMETERS

The quality of welded junction, and particularly the efficiency of the friction welding process, depends on the relative velocity of the friction surfaces and on the axial force applied during the heating period. All other conditions being equal, these factors determine the intensity of the heat introduction for the welding of the given pair of metals.

Yatin Suresh Tambe, Founder & Director – Friction Welding Technologies Pvt. Ltd. (FWT) states, “Our core expertise has been understanding the friction welding process and parameterization, and we have been mentoring industry gurus, competitors, and business giants on these aspects. We have implemented this knowledge into our automated parameterization system. Our wide range of machines have state-of-the-art and highly intuitive software that enable secured process control, user-based access, and control micro-level parameterization, which world leaders like MTI, US, have acknowledged for its capabilities. Today, we have proudly partnered with MTI to provide world-class friction welding machines to the international market.”

ADVANTAGES OF FRICTION WELDING PROCESS

Apart from being a very efficient heat source, friction provides an effective cleaning action. Various foreign inclusions, surface oxides and absorbed films that oppose formation of bonds are destroyed & removed by abrasion produced by friction. Hence this welding is stronger than the conventional welding. But that’s not all, the following advantages of friction welding process, make them the right fit for mission critical applications in Aerospace, Defense, Nuclear industries and more.

1. Fine-grained structure that cannot be obtained through other welding processes

2. Very high static strength

3. The welds are leak-tight

4. Minimal Heat Affected Zone (HAZ)

5. The rotation symmetric heat application, hence high dimensional accuracy

6. Autogenous – no filler material used; the process solely relies on inter-molecular bonding with the original material

7. Machine controlled process, complete automation, including error rectification

8. Parameters can be controlled and monitored

9. Independent of operator skill or attitude

10. No joint preparation required

11. Sustainable and environment friendly as low energy & power required

12. No unhealthy smoke, fumes or gases, or weld spatter, hence it is extremely safe

13. No consumables, no fluxes

14. No solidification defects

15. Dissimilar metals can be welded: Al-Cu, Al-Steel, etc. also including exotic combinations

16. 2-100 times faster than conventional welding

17. Superior to other welding methods from technical and economical perspective

18. Unusually high efficiency coefficient

19. Simplifies manufacturing of complex forging, saves expensive materials

20. Maximum usage of raw materials

These joins can withstand harshest of tests and environments. FWT machine-manufactured friction welding components are being used in several mission critical applications such as BrahMos missiles, Nuclear energy, War tanks, and many more.

INDUSTRIES

We at Friction Welding Technologies Pvt. Ltd. (FWT) have been building friction welding machines and components for wide industrial applications such as:

Nuclear, Defence, Electrical, Automotive, Aerospace, Military, Agriculture & Trucking, Cutting Tools, Oil Refineries, Pumps & Valves, Bimetallic & Special Applications and General Applications

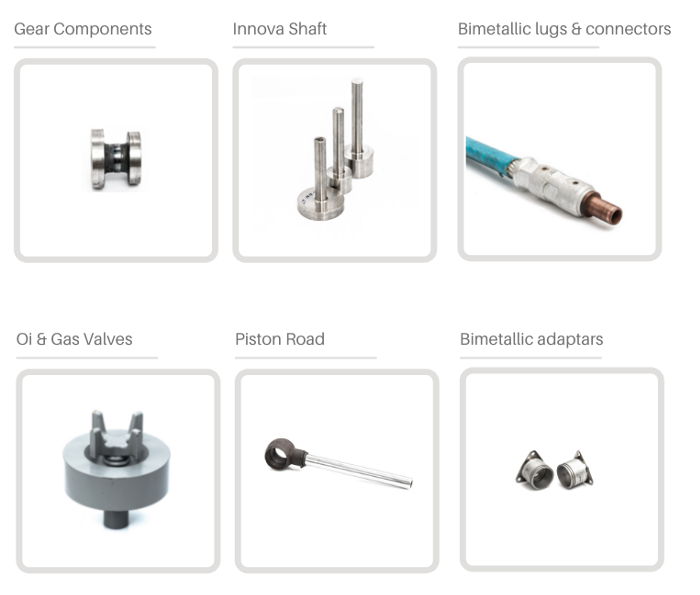

COMPONENTS FRICTION WELDED ON FWT MACHINES

OTHER METAL COMBINATIONS

MS – EN1A

Brass – Aluminum

SS – Pure Aluminum – Aluminum Alloy

SS 321 – Pure Al AA1030 – Titanium AA2219

SAE 8620 – UNS 17400

SS – MS

Forging – SAE 1045

41CR4 – C35

Duplex2205 – SS420

C45 – Steel

HSS – CS

EN-EN8 – EN 18D

SS316 – EN8

MS – ERW Tube

EN1A/SAE1010

CONCLUSION

To come to think of it, friction definitely brings out vulnerabilities between the two entities, wherein they can exchange their reservations, fears, and several other emotions. If this friction is mediated in a healthy and controlled environment, the mutual understanding between the two entities is strengthened. They know each other’s strengths and flaws, and when they work as a team, they are stronger than their individual strengths. Engineering, therefore, might have evolved out of human dynamics, after all.