Precision Bonding for Durable Cutting Tools

Friction Welding for Cutting Tools

Make Your Tools Stand Out

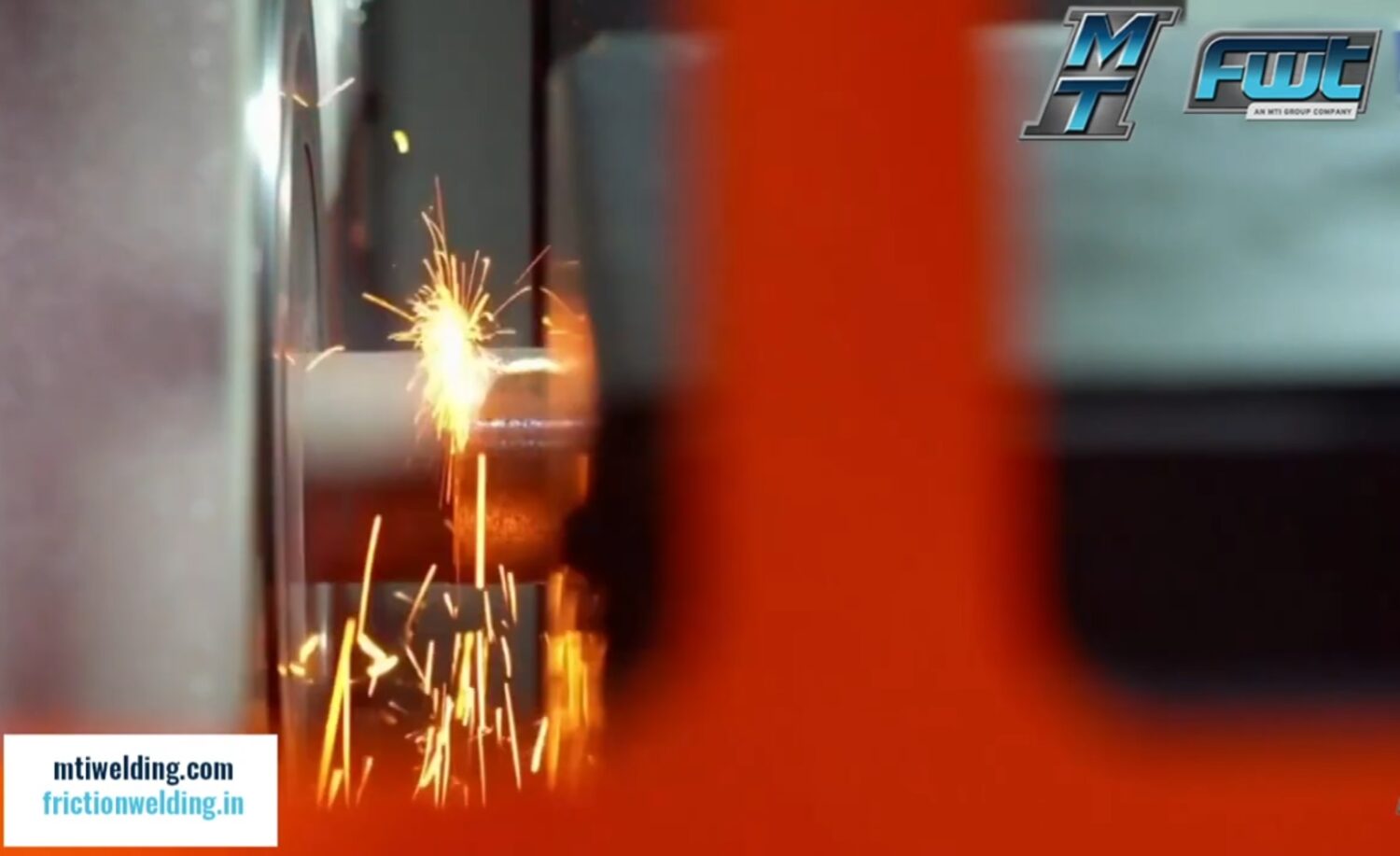

Friction welding enhances the durability and performance of cutting tools by creating strong, defect-free joints without the need for filler materials, reducing potential points of failure. This process allows for seamless bonding of dissimilar materials, optimizing tool functionality and extending their operational life. Additionally, the precision and repeatability of friction welding ensure consistent quality, which is critical for high-performance cutting applications.

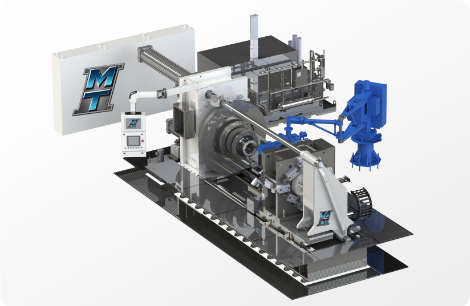

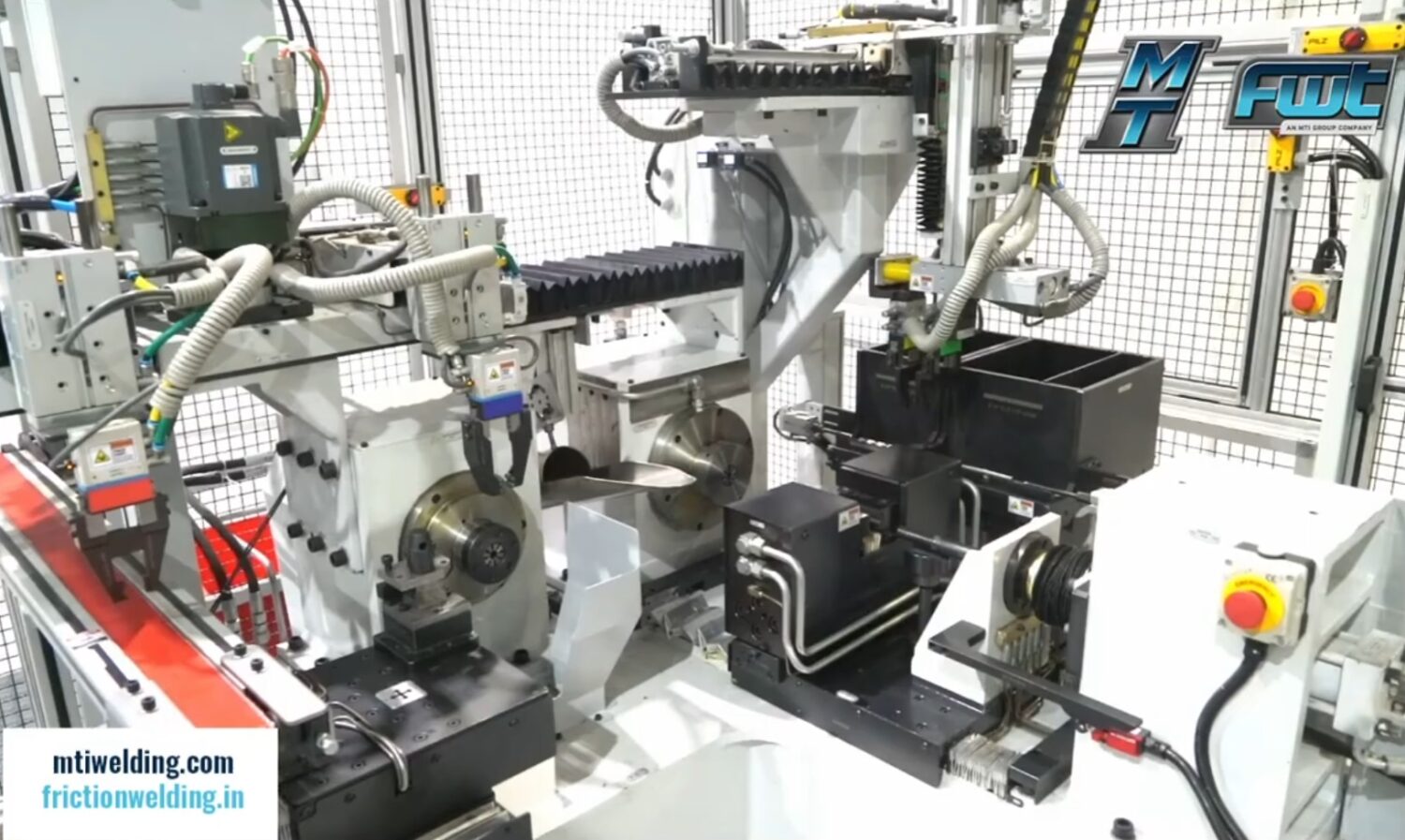

This video shows a fully-automated FWT-3 machine welding drill bits.

Advantages & Benefits

Advancing Cutting Tools with Precision and Efficiency

FWT’s friction welding technologies are setting new standards in consumer product manufacturing. Our innovative solutions offer a perfect blend of speed, sustainability, and quality, enabling manufacturers to meet high-volume demands while delivering superior products to consumers.

Fast, Automated Process

Consumer products are often made in large batches, requiring a joining technique that can keep up with the increasing volumes and pace. Friction welding is a mechanically-controlled process that reduces the cycle time required to create a strong bond. Additionally, our friction welding cells can be built with robots and gantry systems, delivering a fully automated process for seamless production.

Green Technology

Friction welding is an eco-friendly technology that does not emit smoke, fumes, or gases. Friction welding does not require consumables such as flux or filler material, reducing your carbon footprint all the way down your supply chain as less material and energy is used.

Smooth, Clean Welds

Friction welding delivers smooth, clean welds for the consumer products industry by using a solid-state process that avoids melting, thus preventing defects like porosity and contamination. The process also reduces the need for post-weld finishing, saving time and costs. These benefits enhance product reliability and customer satisfaction, giving manufacturers a competitive edge.

Consumer products are often made in large batches, requiring a joining technique that can keep up with the increasing volumes and pace. Friction welding is a mechanically-controlled process that reduces the cycle time required to create a strong bond. Additionally, our friction welding cells can be built with robots and gantry systems, delivering a fully automated process for seamless production.

Friction welding is an eco-friendly technology that does not emit smoke, fumes, or gases. Friction welding does not require consumables such as flux or filler material, reducing your carbon footprint all the way down your supply chain as less material and energy is used.

Friction welding delivers smooth, clean welds for the consumer products industry by using a solid-state process that avoids melting, thus preventing defects like porosity and contamination. This results in aesthetically pleasing and structurally sound joints, which are crucial for the quality and durability of consumer goods. The process also reduces the need for post-weld finishing, saving time and costs. These benefits enhance product reliability and customer satisfaction, giving manufacturers a competitive edge.

Our Commitment

Quality is at the core of our innovation

With an in-house innovation team and a substantial investment in R&D, we continuously set new industry standards in quality, systems, and best practices. Our commitment to excellence is reinforced by our ISO 9001:2015 certification. For customers in Europe, FWT machines are designed and manufactured to fully comply with European safety requirements for CE.

Friction Welding Machines for Cutting Tools

Machine-welded parts and products mean fewer errors and more savings. They boast cleaner aesthetics and improved strength, joining metals incompatible with traditional welding.

There is a reason why FWT-built friction welders are still operating in production worldwide. FWT can design and operate semi and fully automated welders for precision and dependable quality.

Friction Welding Machines for Cutting Tools

Machine-welded parts and products mean fewer errors and more savings. They boast cleaner aesthetics and improved strength, joining metals incompatible with traditional welding.

There is a reason why FWT-built friction welders are still operating in production worldwide. FWT can design and operate semi and fully automated welders for precision and dependable quality.

ROTARY FRICTION WELDING

Improve your production time with FWT’s Rotary friction welder machines’ fast weld cycles. Our advanced controls ensure error-free precision.

Explore Our Parts Gallery

Curious if your desired shapes and materials are feasible? Look no further. View our parts gallery for a closer look at precision-engineered components and past projects.

Contract Manufacturing Services

Have a project in mind? We’ve got you covered. From consultation to testing and manufacturing, FWT offers the expertise and resources to complete your project seamlessly, all in one place.

Contract Manufacturing Services

Have a project in mind? We’ve got you covered. From consultation to testing and manufacturing, FWT offers the expertise and resources to complete your project seamlessly, all in one place.

Learning Center

Case Study

Videos

Direct Drive