Robust Joining for the Armed Services

Friction Welding for Defense Applications

Fortify Defense with Advanced Friction Welding Technology

FWT brings extensive expertise and innovation to the defense industry, serving as a trusted partner in advancing India’s defense capabilities. Collaborating closely with Godrej Aerospace, FWT proposed an optimized friction welding solution for the BrahMos missile project, moving away from traditional explosion welding. This shift reduced rejection rates from 85% to zero, underscoring FWT’s impact on manufacturing precision and efficiency.

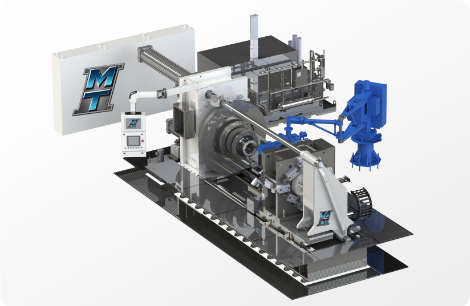

By engineering a custom 50-ton machine that integrates advanced features, including an intuitive interface and flexible parameterization, FWT achieved a solution that met stringent quality requirements and exceeded expectations. Now operational at Godrej, this machine supports the in-house production of critical missile components, strengthening India’s defense manufacturing independence and ensuring the highest standards in quality and reliability.

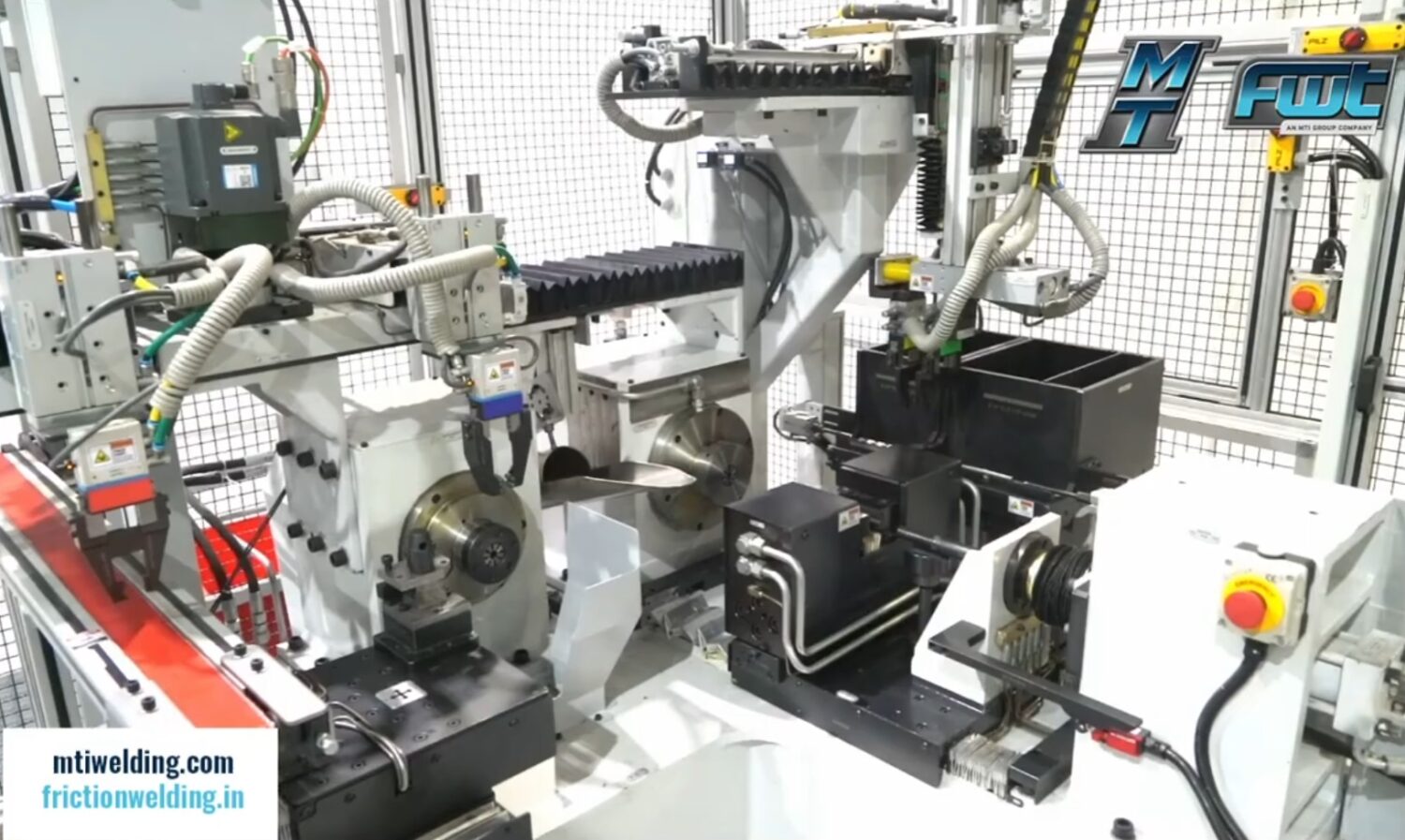

Demonstration of the FWT-30 machine built and designed for the demanding conditions of the defense industry.

Advantages & Benefits

Fortifying National Security with Advanced Welding Solutions

FWT’s friction welding technologies are at the forefront of innovation in defense manufacturing. Our cutting-edge solutions deliver unmatched precision, reliability, and performance, empowering the defense industry to create stronger, lighter, and more efficient equipment for protecting our nation’s interests.

Repeatable, Mechanical Process

Defense-related components and products must be consistently safe and reliable when our country needs them. As a mechanical process, friction welding is highly repeatable, resulting from predetermined calculations and measurements that ensure each weld is forged of consistent, high-quality.

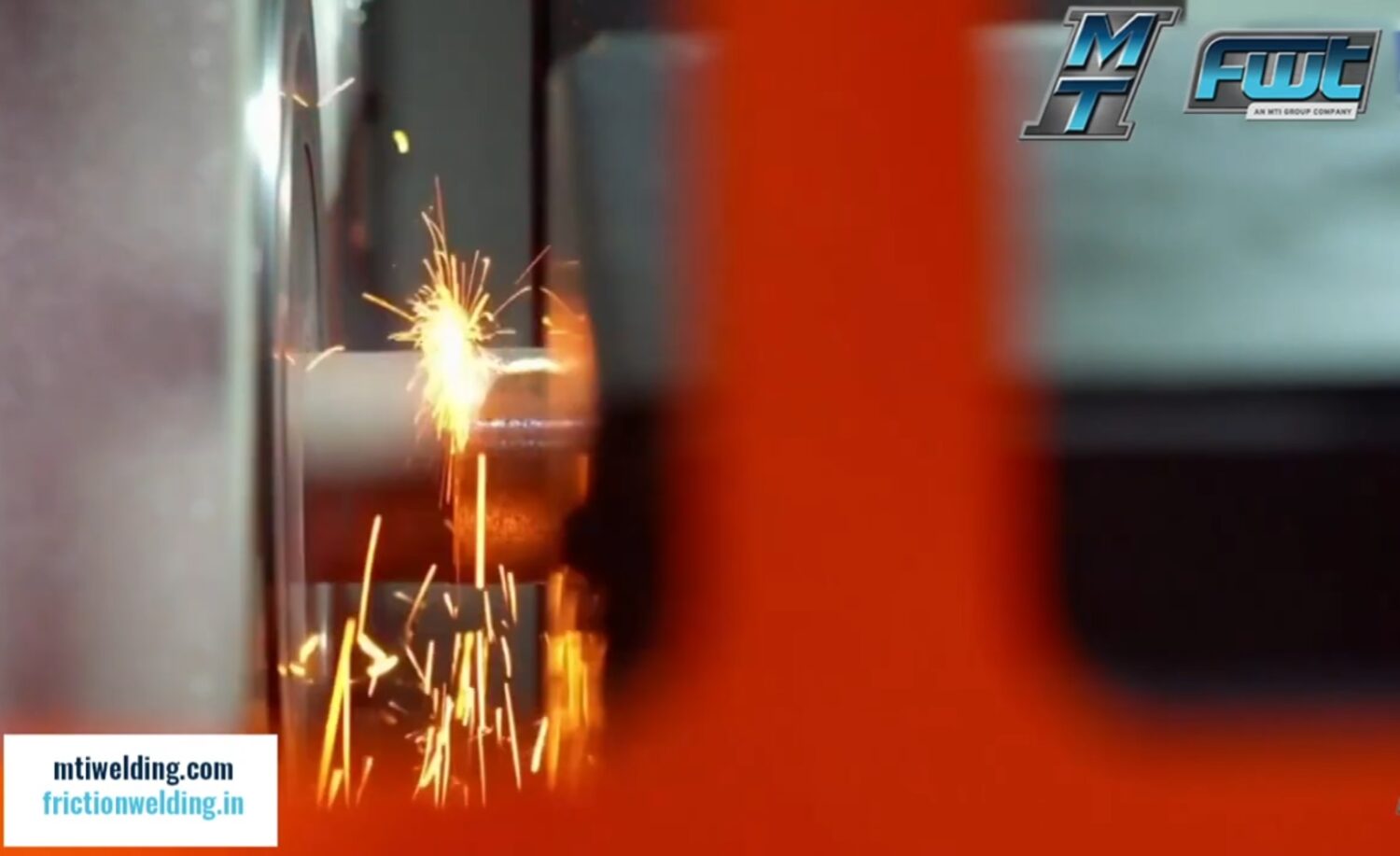

Strong Welds

Friction welding is a solid-state process where, unlike fusion methods, does not melt the materials being joined. Instead, the materials are brought to a plasticized state, allowing them to seamlessly forge together while retaining the parent material properties. With forged welding properties, friction welding fortifies any defense application.

Lightweighting

Lightweighting benefits the defense industry by reducing the weight of military vehicles and equipment, enhancing mobility and fuel efficiency. The strong, reliable joints created by friction welding allow for the use of advanced lightweight materials without compromising structural integrity. This improves performance and operational range while lowering transportation and deployment costs. Additionally, lighter equipment can improve maneuverability and speed, providing tactical advantages in the field.

Bimetallic Joining

Bimetallic joining is beneficial for the defense industry because it enables the combination of different materials with complementary properties, such as strength and corrosion resistance. This allows for the creation of specialized components that can withstand harsh environmental conditions. The solid-state nature of friction welding ensures strong, reliable joints without compromising the integrity of the materials, crucial for defense applications where durability and performance are paramount.

Defense-related components and products must be consistently safe and reliable when our country needs them. As a mechanical process, friction welding is highly repeatable, resulting from predetermined calculations and measurements that ensure each weld is forged of consistent, high-quality.

Friction welding is a solid-state process where, unlike fusion methods, does not melt the materials being joined. Instead, the materials are brought to a plasticized state, allowing them to seamlessly forge together while retaining the parent material properties. With forged welding properties, friction welding fortifies any defense application.

Lightweighting benefits the defense industry by reducing the weight of military vehicles and equipment, enhancing mobility and fuel efficiency. The strong, reliable joints created by friction welding allow for the use of advanced lightweight materials without compromising structural integrity. This improves performance and operational range while lowering transportation and deployment costs. Additionally, lighter equipment can improve maneuverability and speed, providing tactical advantages in the field.

Bimetallic joining is beneficial for the defense industry because it enables the combination of different materials with complementary properties, such as strength and corrosion resistance. This allows for the creation of specialized components that can withstand harsh environmental conditions. The solid-state nature of friction welding ensures strong, reliable joints without compromising the integrity of the materials, crucial for defense applications where durability and performance are paramount.

Our Commitment

Quality is at the core of our innovation

With an in-house innovation team and a substantial investment in R&D, we continuously set new industry standards in quality, systems, and best practices. Our commitment to excellence is reinforced by our ISO 9001:2015 certification. For customers in Europe, FWT machines are designed and manufactured to fully comply with European safety requirements for CE.

Friction Welding Machines for the Defense Industry

The advantage of machine-welded parts and structures is the perpetual quality of production. Friction welding machines offer more precision, a faster production rate, and fewer errors, leading to economic efficiency.

We are here to collaborate with you on joining defense components or designing and building friction welding machines for your defense needs.

Friction Welding Machines for the Defense Industry

The advantage of machine-welded parts and structures is the perpetual quality of production. Friction welding machines offer more precision, a faster production rate, and fewer errors, leading to economic efficiency.

We are here to collaborate with you on joining defense components or designing and building friction welding machines for your defense needs.

ROTARY FRICTION WELDING

Defense industry engine manufacturers trust the MTI Group’s friction welders for critical armored vehicle components.

FRICTION STIR WELDING

FWT is the trusted service for friction stir welding of stiffened panels for armored vehicles and cold plates in defense systems.

The MTI Group of Companies offers extended technology solutions such as Linear, Low Force, and Plug Welding out of our US facility.

Explore Our Parts Gallery

Are you wondering if the materials and shapes you have in mind will work for defense applications? Examine our samples to find the materials, uses, and geometric fittings necessary for your next defense project.

Contract Manufacturing Services

Have an idea for a defense project? FWT provides consulting, testing, and manufacturing. We collaborate with clients to develop and create their friction welding machines or parts. We also handle their project for them. We’ll have everything you need to be successful in your project.

Contract Manufacturing Services

Have an idea for a defense project? FWT provides consulting, testing, and manufacturing. We collaborate with clients to develop and create their friction welding machines or parts. We also handle their project for them. We’ll have everything you need to be successful in your project.

Learning Center

Case Study

Videos

Direct Drive