What is Friction Welding?

A Guide to Friction Welding Technologies

Friction welding is a solid-state joining technique that welds a joint between two components through mechanical heat friction. This welding technology has been a trusted and effective joining process for decades, evolving into various specialized techniques such as Rotary, Linear, Friction Stir, and Low Force friction welding. FWT is part of the MTI Group of Companies which is the only manufacturer that offers all of these friction welding processes. We are uniquely positioned to recommend and supply the best technology for your application. Our decades of experience in the industry provide us with a deep understanding of the nuances and advantages of each method, ensuring that we can provide a tailored solution to meet your specific needs.

By offering the complete range of friction welding options, we can help you achieve the highest quality, efficiency, and performance in your welded assemblies. Trust us to guide you in selecting the optimal welding process for your application, backed by our unparalleled experience and innovation in the field.

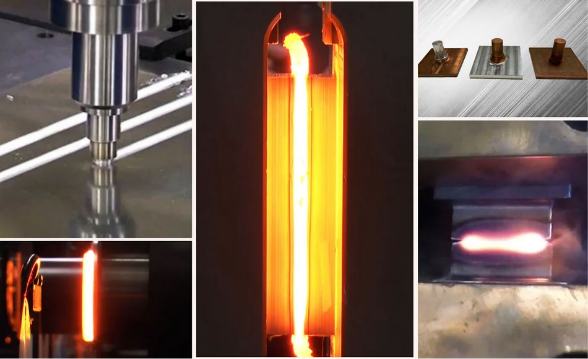

Rotary Friction Welding

Efficient, high-strength joining with direct drive, inertia or hybrid.

Rotary Friction welding is a solid-state process where one component is rotated at high speed and pressed against a stationary part. The resulting friction generates heat, forging the parts together seamlessly.

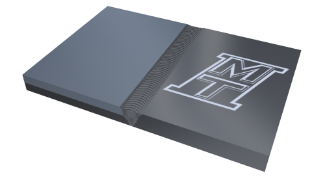

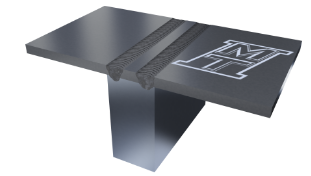

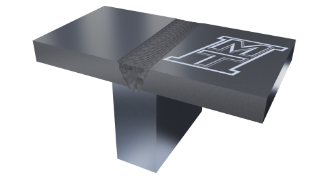

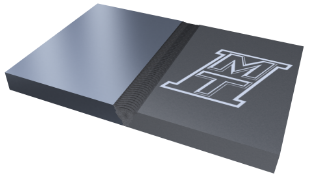

Friction Stir Welding

Transforming industries across the globe

Friction Stir Welding creates friction with a rotating pin tool that stirs across the materials in a weld line, effective for virtually defect-free bonding in aerospace, automotive, and other industries.

Low Force Friction Welding

MTI’s newest friction welding technology

Low Force friction welding uses external heat to reduce the forces of traditional welding methods to create a solid-state weld.

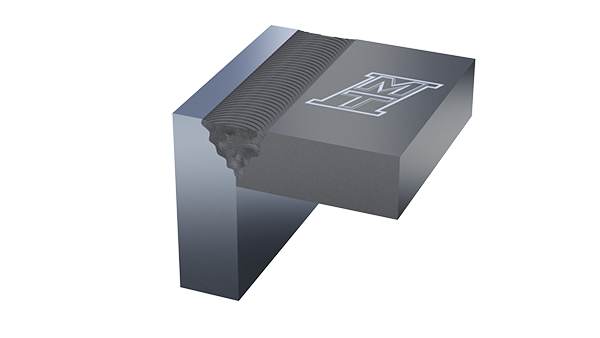

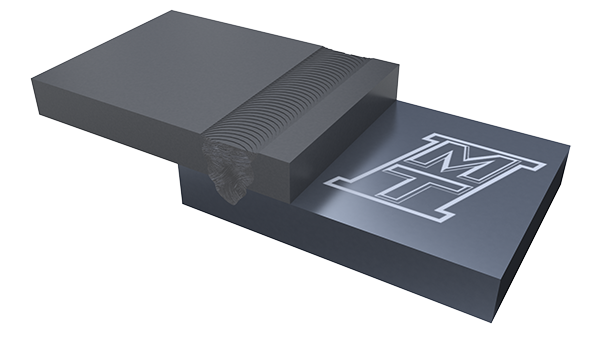

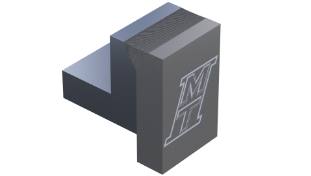

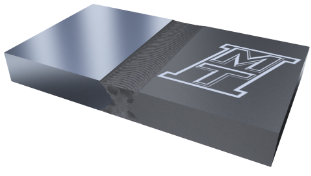

Linear Friction Welding

Widely used in the Aerospace industry and ideal for complex components

Linear friction welding joins two components by holding one part stationary while the other is pressed against it and moved in a high-speed linear motion.

Check Your Material Combination & Geometry

Can Your Application Be Friction Welded?

Compatible Welds

|

Not Seeing Your Combination Of Materials?

That doesn’t mean it can’t be done. Many of our material combinations are also proprietary. That’s why several of our customers use MTI’s in-house metallurgy lab, which will test your materials for strength and durability to see if friction welding is the right process for you.

Please note Weld strength is dependent on materials & geometry.

Joint Geometries

Friction Welding can join a wide range of part geometries

Let’s talk about the specifics of your project:

Example Parts

Friction Welding can join a wide range of parts and geometries

Application

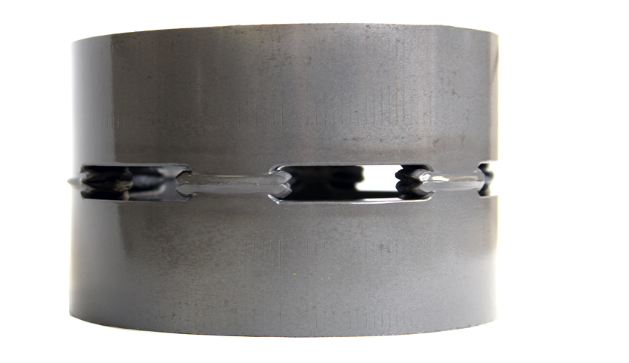

Castellated Tube

Application

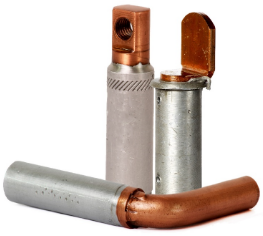

Bimetallic electrical connectors

Application

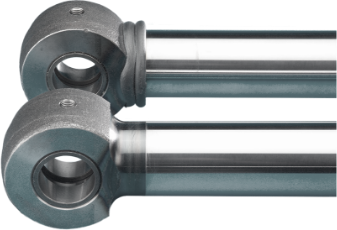

Hydraulic Cylinder Rod

Application

Linear Aerospace Development

Application

Weld Orientation Development

Application

Electronic Enclosure

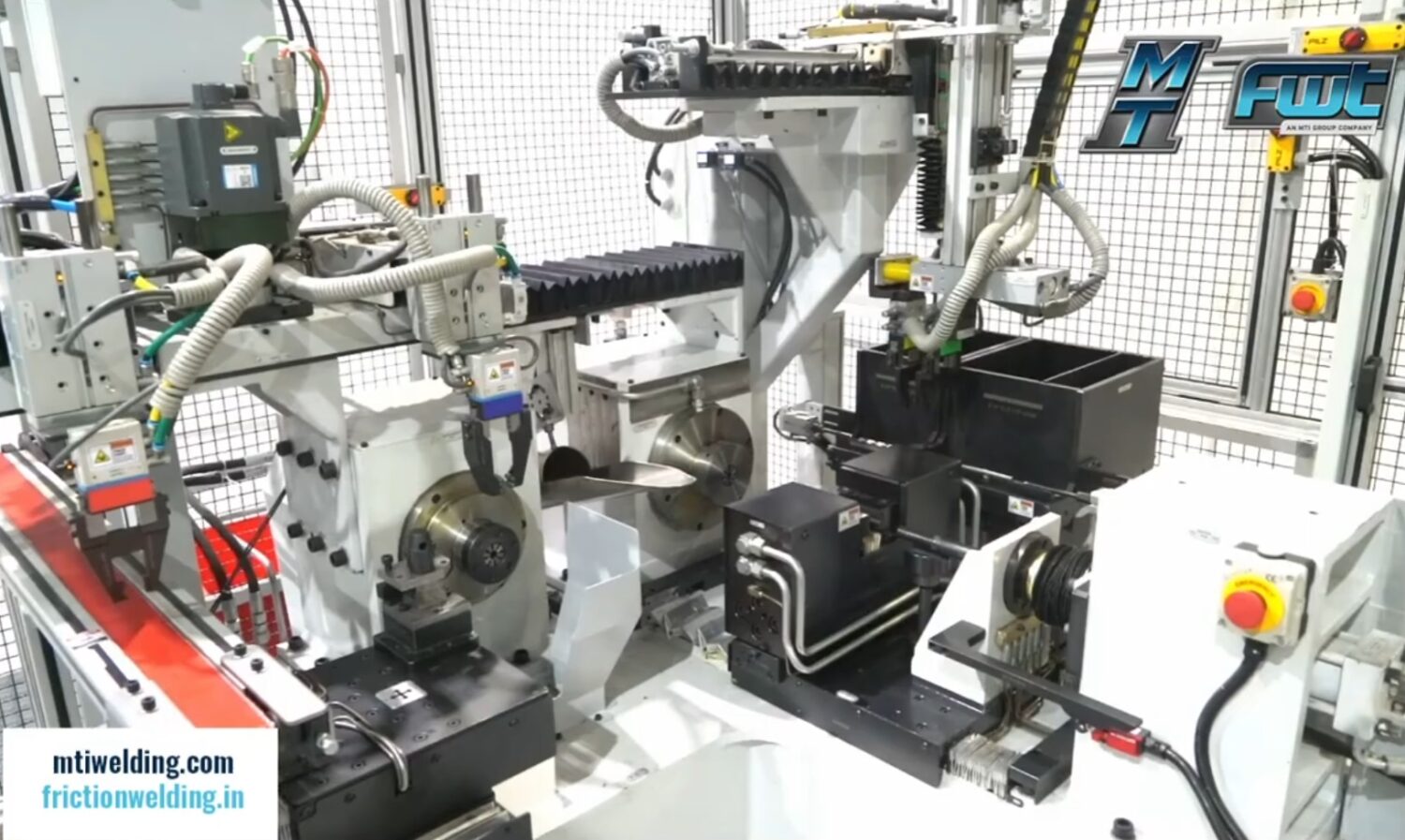

Contract Friction Welding

We don’t just build friction welders – we operate them, too. When you partner with our global Contract Friction Welding teams, we will handle your project from start to finish on our state-of-the-art friction welding machines. Whether you need one part every year or one part every minute, we are here to help you reach your production goals across the globe.

Contract Friction Welding

We don’t just build friction welders – we operate them, too. When you partner with our global Contract Friction Welding teams, we will handle your project from start to finish on our state-of-the-art friction welding machines. Whether you need one part every year or one part every minute, we are here to help you reach your production goals across the globe.

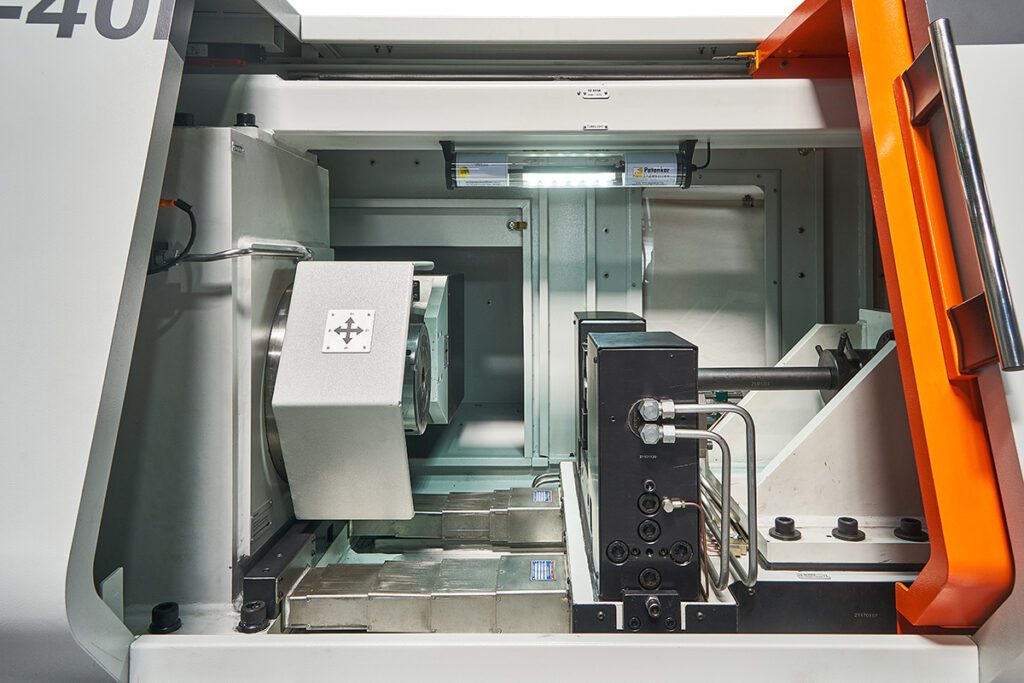

Friction Welding Machines

The FWT range of machines is rugged and built to last. Loaded with intelligent control systems, our machines can rise up to any challenge – be it the nature of metals, applications, dimensions or geometry.

Learning Center

Case Study

Videos

Direct Drive

FWT White Paper

FWT: A cost-effective joining solution for the automotive industry

In the following pages, we will outline the benefits of friction welding, define the different types of friction welding, and describe the friction welding process. We’ll also mention current issues faced by the automotive industry. And finally, we’ll show how FWT is an effective tool to overcome these challenges and achieve manufacturing goals.